Inductive Vs Capacitive Sensor

Inductive Vs Capacitive Sensor - However, for certain use cases, inductive sensing offers greater reliability. Capacitive sensors are smaller, simpler, less expensive & use less power. Web when it comes to inductive and capacitive position sensors, each is built quite differently, meaning that each technology is suited to particular geometries and applications. Web explore different types of proximity sensors: These sensors are widely used in industries and fields for industrial automation, robotics, consumer electronics, manufacturing, automotive and. These two sensors differ in the materials that they sense, to how they operate, as well as when and how each of their principles were discovered.

Web the primary difference between inductive and capacitive proximity sensors is the sensing method: Web ti's inductive and capacitive portfolio consist of ldc and fdc devices. Inductive sensors use a coil to generate an electromagnetic field. This limits suitable targets to metal objects (for the most part). Web a key step in selecting a position sensor is understanding the requirements of sensor size, resolution, repeatability, accuracy, mounting constraints and environmental ruggedness.

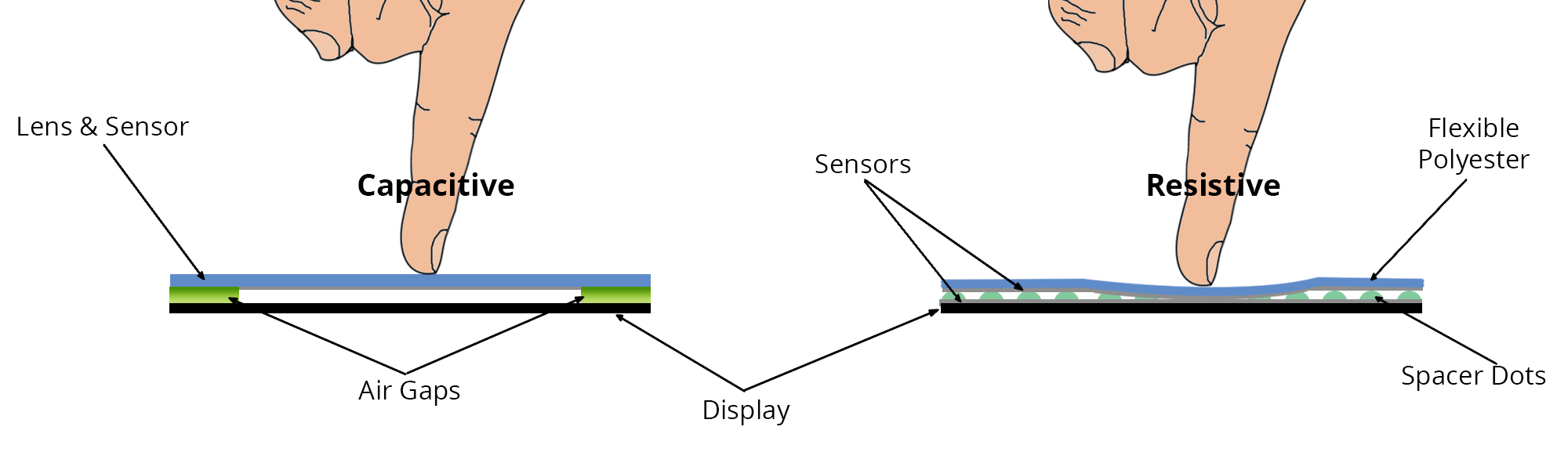

Then when your finger which comes either in contact or really close the capacitance of the circuit changes and a touch is detected. Web capacitive sensing is undeniably useful in a great many applications. This paper discusses the technologies of capacitive and inductive sensors and concludes with a key feature comparison. Web in this article, nishant discusses capacitive sensing and inductive sensing, each in the context of their use in embedded applications. Web the primary difference between inductive and capacitive proximity sensors is the sensing method:

Web capacitive sensors measure change in capacitance while inductive sensors measure change in electromagnetic fields. Web proximity sensor working inductive vs. Consider the use case of a bluetooth speaker that needs to be water resistant and is intended for use in up to two feet of water for half an hour. Web ti's inductive and capacitive portfolio consist of ldc.

Web as shown in the table above, distinguishing between capacitive vs inductive sensors is not an easy task. These sensors are widely used in industries and fields for industrial automation, robotics, consumer electronics, manufacturing, automotive and. 10 to 50 hz, with a sensing distance from 3 to 60. Web in this article, nishant discusses capacitive sensing and inductive sensing, each.

Web if probing speed is extremely critical in your application, an inductive or capacitive sensor might be the best choice for you. Yet, there are specific attributes for which each is a better choice. Web ti's inductive and capacitive portfolio consist of ldc and fdc devices. With no target present, the field is at its strongest amplitude. Web inductive sensors.

Inductive sensors detect the proximity of metal targets to an inductive coil sensor, whereas capacitive sensors detect the change in capacitance between a sensor and electrode. This limits suitable targets to metal objects (for the most part). In this article we will discuss the differences between the inductive and capacitive proximity switches, and explain how they work with a number.

Web the easiest option are inductive sensors, but those only detect metals and are useless for glass, then you’ve got optical ones, which can detect any surface as long as it’s not totally transparent, mechanical ones that physically extend to the surface and touch it, and lastly capacitive sensors that will detect every surface and then some. These sensors are.

Web the differences are significant as compared to radar. Web capacitive sensor and inductive sensor are some of them. Inductive sensors detect the proximity of metal targets to an inductive coil sensor, whereas capacitive sensors detect the change in capacitance between a sensor and electrode. This paper discusses the technologies of capacitive and inductive sensors and concludes with a key.

Web in this article, nishant discusses capacitive sensing and inductive sensing, each in the context of their use in embedded applications. Capacitive sensors use an electric field. These two sensors differ in the materials that they sense, to how they operate, as well as when and how each of their principles were discovered. Web a key step in selecting a.

Web if probing speed is extremely critical in your application, an inductive or capacitive sensor might be the best choice for you. These two sensors differ in the materials that they sense, to how they operate, as well as when and how each of their principles were discovered. Web capacitive sensor and inductive sensor are some of them. Web the.

While the inductive sensor detects if the. This paper discusses the technologies of capacitive and inductive sensors and concludes with a key feature comparison. Inductive sensors use a coil to generate an electromagnetic field. When a target is present, the electromagnetic field weakens. In this article we will discuss the differences between the inductive and capacitive proximity switches, and explain.

This limits suitable targets to metal objects (for the most part). Consider the use case of a bluetooth speaker that needs to be water resistant and is intended for use in up to two feet of water for half an hour. In capacitive touch they lay down a grid of indium tin oxide (ito) and connect it to some sensors..

Inductive Vs Capacitive Sensor - Capacitive sensors are smaller, simpler, less expensive & use less power. The capacitive sensor, for this case, detects the filling level of the liquid. Web understanding the difference between capacitive and inductive sensors begins by looking at how they are constructed. Web capacitive sensors measure change in capacitance while inductive sensors measure change in electromagnetic fields. Capacitive sensing involves charging up plates, so it is somewhat slower than inductive: At the centre of a capacitive probe is the sensing element. Web proximity sensor working inductive vs. Web the easiest option are inductive sensors, but those only detect metals and are useless for glass, then you’ve got optical ones, which can detect any surface as long as it’s not totally transparent, mechanical ones that physically extend to the surface and touch it, and lastly capacitive sensors that will detect every surface and then some. These two sensors differ in the materials that they sense, to how they operate, as well as when and how each of their principles were discovered. This limits suitable targets to metal objects (for the most part).

Web in this article and video, we will look at the difference between inductive and capacitive proximity sensors. Web comparison of capacitive with induction sensors. In order to be sensed by an inductive sensor an object must be conductive. 10 to 50 hz, with a sensing distance from 3 to 60. Web understanding the difference between capacitive and inductive sensors begins by looking at how they are constructed.

Consider the use case of a bluetooth speaker that needs to be water resistant and is intended for use in up to two feet of water for half an hour. Web comparison of capacitive with induction sensors. Web the primary difference between inductive and capacitive proximity sensors is the sensing method: Web understanding the difference between capacitive and inductive sensors begins by looking at how they are constructed.

10 to 50 hz, with a sensing distance from 3 to 60. However, for certain use cases, inductive sensing offers greater reliability. Inductive, capacitive, ultrasonic, photoelectric, and magnetic—each with unique functions and applications.

Web a key step in selecting a position sensor is understanding the requirements of sensor size, resolution, repeatability, accuracy, mounting constraints and environmental ruggedness. While the inductive sensor detects if the. Web the primary difference between inductive and capacitive proximity sensors is the sensing method:

Inductive Sensors Use A Coil To Generate An Electromagnetic Field.

In this article we will discuss the differences between the inductive and capacitive proximity switches, and explain how they work with a number of applications as an example. Capacitive sensors explained with 3d animationscience and technology 3d animations videos related to electrical & elec. Web capacitive sensors measure change in capacitance while inductive sensors measure change in electromagnetic fields. Web it's just the method they use to detect the touch.

Web Ti's Inductive And Capacitive Portfolio Consist Of Ldc And Fdc Devices.

Capacitive sensors are smaller, simpler, less expensive & use less power. 10 to 50 hz, with a sensing distance from 3 to 60. Consider the use case of a bluetooth speaker that needs to be water resistant and is intended for use in up to two feet of water for half an hour. Web some inductive and capacitive position sensors can look quite similar and so it is no surprise that design engineers can find the differences between them confusing.

Web When It Comes To Inductive And Capacitive Position Sensors, Each Is Built Quite Differently, Meaning That Each Technology Is Suited To Particular Geometries And Applications.

So, this article briefly explains a capacitive sensor and its works with applications. This piece of stainless steel generates the electric field. Web capacitive sensor and inductive sensor are some of them. In capacitive touch they lay down a grid of indium tin oxide (ito) and connect it to some sensors.

Web In This Article And Video, We Will Look At The Difference Between Inductive And Capacitive Proximity Sensors.

Web comparison of capacitive with induction sensors. These sensors are widely used in industries and fields for industrial automation, robotics, consumer electronics, manufacturing, automotive and. Web the easiest option are inductive sensors, but those only detect metals and are useless for glass, then you’ve got optical ones, which can detect any surface as long as it’s not totally transparent, mechanical ones that physically extend to the surface and touch it, and lastly capacitive sensors that will detect every surface and then some. Web as shown in the table above, distinguishing between capacitive vs inductive sensors is not an easy task.